Wednesday, 28 November 2012

Photo Corners

Finished Box

Here it is my finished box. Massively happy with the results i think it just show how much hard work i have put into making this. The measurements i took make everything fit together like a glove. I don't think it is air tight but its pretty close.

The box looks really good when its holding coffee also. i think this is a good start to my brief i can't wait to get making the other products to go with it.

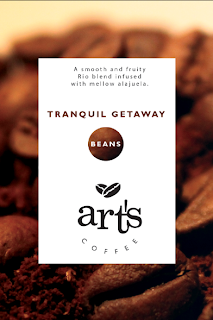

Photos Of Coffee

I wanted to take some of my own imagery for the project just as an experiment to see wether it will be suitable to use for the packaging. I took the photos on a white piece of paper using a couple of desk lamps to light them up.

The lamps added a orangy ting to the photos and i should of altered the white balance before i took the photos. This is a small selection of the photos and i feel like the close up ones came out better. A macro lens would f been perfect to use and given me really good detail.

I really like the close up shots and the blend off full beans and ground works really well. I think i might actually use these for my project i will see how i can integrate the into my brief.

Laser-cutting acrylic

I had a bit of a nightmare laser-cutting the fronts and tops for the coffee container. All i wanted to do is raster the logo so it kind of colours it in rather than cuts out.

This is my first raster attempt . Can bearly see it at all so i wanted it deeper.

Here you can see it a bit better but still really faint.

These next few images above are my attempts of cutting this deeper one of them worked and there was a lot more attempts that i didn't photo. i was running out of acrylic and i think i nearly flipped out. I knew what i was doing just some of the million setting must of been wrong.

I also had to change the design and make it a stencil chape otherwise it colour in the centre of the a' and between the t and s.

I finally got it with my last few gaps on the acrylic i can't even tell you why these came out im sure i did this from the beginning. I am massively happy with the results although i think i have sprouted a few grey hairs because of it.

Putting box together

I had brought some small tac nails to put the box together but i felt like the wood may have a possibility of cracking. I was pointed towards wood glue by someone was a bit unsure it it would hold the ware and tear of daily use. After attempting to pry two pieces of wood apart that had used the glue i was beaten so chose to use it.

The result is very promising and i was able to stick the pieces together with ease and with a flawless edge. only time will tell it it holds up.

Monday, 26 November 2012

New Wooden Packaging (Not Burn't)

I had A woodwork technician help me cut and engrave my box. I took down a printed net with all the measurements on so it was a very quick process compared to lazer-cutting it. I plan to lazer cut the acrylic tomorrow to go with the wood.

the pieces fit perfectly and there are no burn marks what so ever. Probably going to give it a sand to give it a nicer finish

Next Weeks Plan

Monday

Tuesday

Wednesday

Thursday

- Made wooden section of packaging. (well done)

- get acrylic ready for cutting tomorrow

- Get nails to put wooden packaging.

- Blog as much as you can!!

- Sign up for tutorials.

Tuesday

- Photography and Design for print (FULL DAY)

- Packaging designs for coffee 10x15 size

- Design small cards for coffee ranges

- Come up with small box net for chocolate covered coffee beans

Wednesday

- Finish all coffee designs for test print

- Look at potential stocks.

Thursday

- Print test coffee packaging don't leave till its sorted.

- Book laser cutter for today or tomorrow. (Loose tags)

- Blog

Friday

- Book out lights for weekend with Chris.

- laser cut Loose tags

- Carry on with working

- Laser cut acrylic for coffee had no time to fit it in this week

Weekend

- Photograph Loose and Prolifera on saturday in uni.

Laser Cutting Loose

We wanted to make the clothes seem more professional so we planned to created swing tags to attach on the clothes. Chris wanted to use wood but i suggested to use mount-board as i thought it would be a suitable thickness, sturdy and relatively quick to cut out.

I produced 2 different designs on both white and black. we cut enough out to go with all the clothes. I think we will attach the tags with safety pins but i need to see if they damage the clothes.

Lazer cutting

I had my designs packaging designs ready for lazer-cutting on friday so i could put the box together over the weekend.

I was able to lazer cut a 2mm troff for the acetate to slide into so i had to get a technician to help me set up the right setting to do that.

As my Wood is 6 mm it is the thickest possible material that you can cut on the lazer cutter so i knew it would have to cut round the shape a number of times. But i wasn't ready for the pain staking wait that i was in for. It took a good hour or so to cut round everything and also the troff. I was aware that it might not of cut all the way through and i would have to send it around again. I was correct it didn't cut all the way thought and i already had some serious burn marks as the wood got extremely hot. I sent it round again with took ages.

I was able to lazer cut a 2mm troff for the acetate to slide into so i had to get a technician to help me set up the right setting to do that.

As my Wood is 6 mm it is the thickest possible material that you can cut on the lazer cutter so i knew it would have to cut round the shape a number of times. But i wasn't ready for the pain staking wait that i was in for. It took a good hour or so to cut round everything and also the troff. I was aware that it might not of cut all the way through and i would have to send it around again. I was correct it didn't cut all the way thought and i already had some serious burn marks as the wood got extremely hot. I sent it round again with took ages.

As you can see above the box has burn't really badly due to the intese heat cause by the really concentrarted heat off the laser cutter.

There is a whole the back i forgot to take into account that this would happen if i cut to the end.

This is the design i sent to laser cutter. i minimised the lines to be cut by putting the pieces together this would also insure that the pieces fit together.

Subscribe to:

Comments (Atom)